- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

LINGWEN

Single-Use Pen Type IV Cannula Assembly Machine

1、Process flow chart

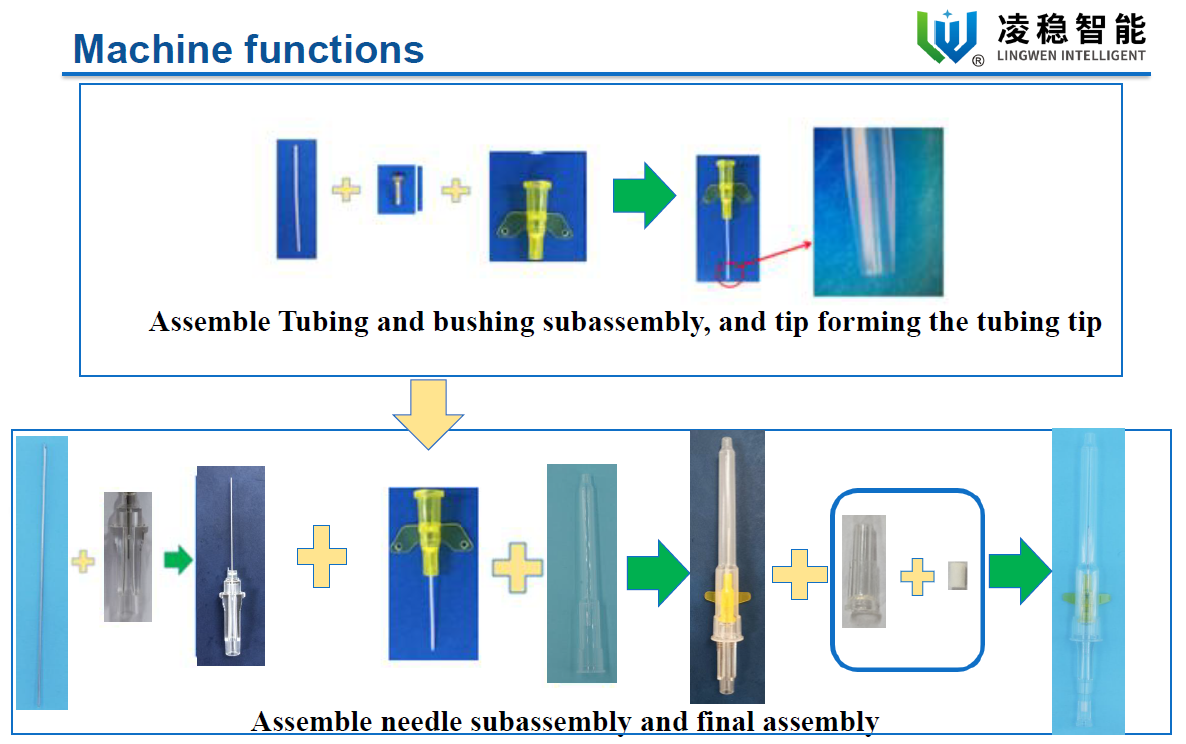

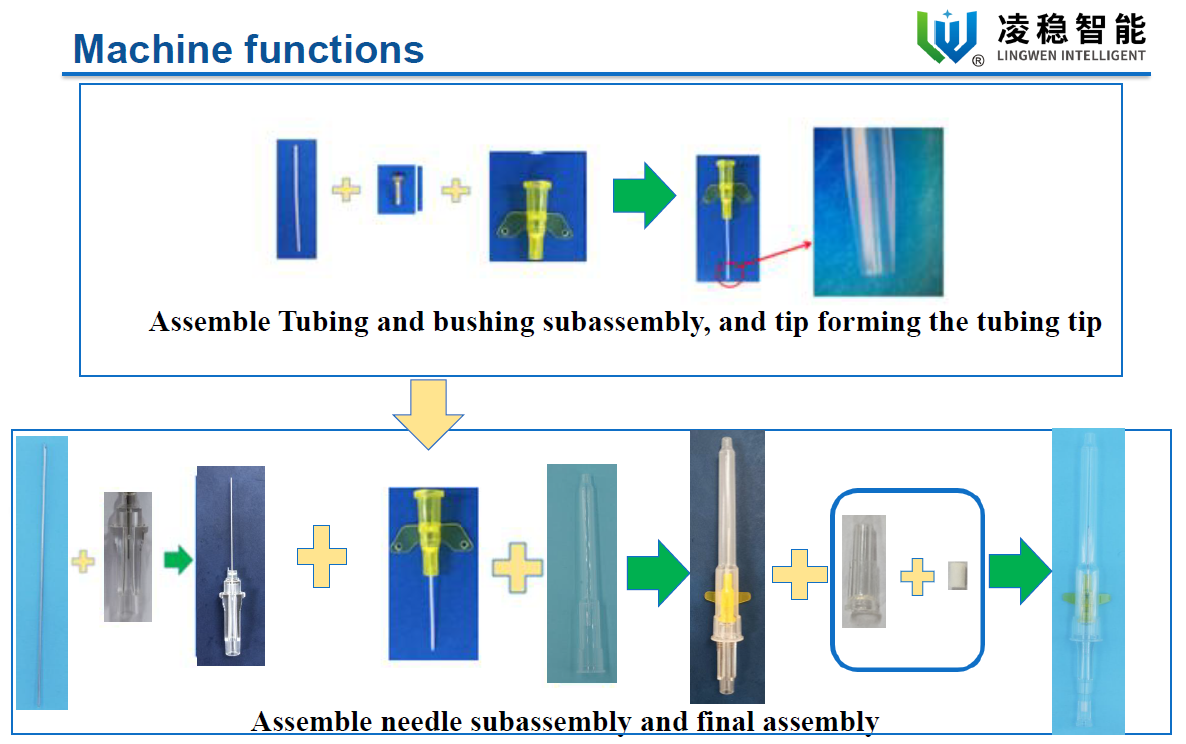

Iv catheter wing housing assembly-Tip forming assembly- needle Assembly -Finaly Assembly Machine

2、Machine Functions

1). Suitable for wing type and pen type IV cannula

2). Customized automated tipping technology for lower penetration forces.3. Minimum clearance between catheter and needle to avoid peel-back.

3). IV catheter production line control and adjust trim length automatically

4)、Equipment monitoring needle burr, angle, orientation, needle perpendicularity ,needle value by CCD

5)、Needle crosses Teflon holder,proportion of damaged needle is controlled within 1‰

6)、Extension tube of PU and FEP with coil or fixed length tube

7)、Device main functions are assemble all components of IV cannula :Teflon catheter , Teflon holder, needle, needle hub, wing house, injection port cap, stopper, filter , flashback chamber ,protective cap, apply glue UV adhesive ,apply silicone oil, curing, test drawing force .

8)、Diversified production line pipeline type, circular circulation line, rotating table type to meet the needs of different customers.

3、lead time

4 months

4、Packaging

Wooden case

5、warranty time

1 year

6、After-sales service

support 7*24H,training support,Installation, wear parts...

Automatic assembly machine for pen type IV cannula is used for Keeping assembling precisely,

The machine is equipped with transfer belts between 3 individual machine.

Single-Use Pen Type IV Cannula Assembly Machine

1、Process flow chart

Iv catheter wing housing assembly-Tip forming assembly- needle Assembly -Finaly Assembly Machine

2、Machine Functions

1). Suitable for wing type and pen type IV cannula

2). Customized automated tipping technology for lower penetration forces.3. Minimum clearance between catheter and needle to avoid peel-back.

3). IV catheter production line control and adjust trim length automatically

4)、Equipment monitoring needle burr, angle, orientation, needle perpendicularity ,needle value by CCD

5)、Needle crosses Teflon holder,proportion of damaged needle is controlled within 1‰

6)、Extension tube of PU and FEP with coil or fixed length tube

7)、Device main functions are assemble all components of IV cannula :Teflon catheter , Teflon holder, needle, needle hub, wing house, injection port cap, stopper, filter , flashback chamber ,protective cap, apply glue UV adhesive ,apply silicone oil, curing, test drawing force .

8)、Diversified production line pipeline type, circular circulation line, rotating table type to meet the needs of different customers.

3、lead time

4 months

4、Packaging

Wooden case

5、warranty time

1 year

6、After-sales service

support 7*24H,training support,Installation, wear parts...

Automatic assembly machine for pen type IV cannula is used for Keeping assembling precisely,

The machine is equipped with transfer belts between 3 individual machine.