- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

Lingwen21

LW

Automatic Assembly Machine for Blunt Needle

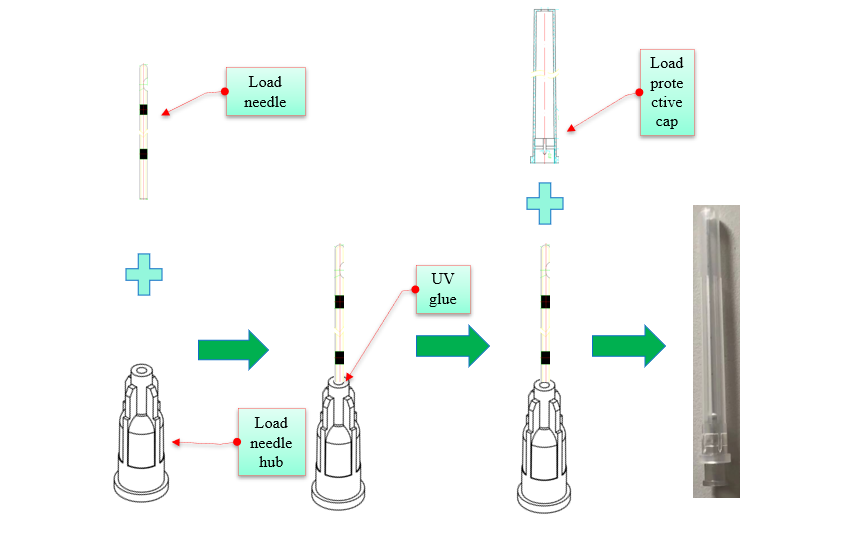

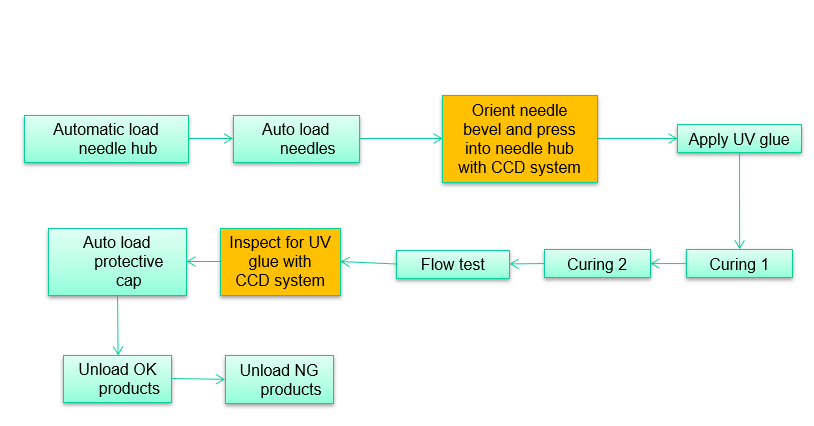

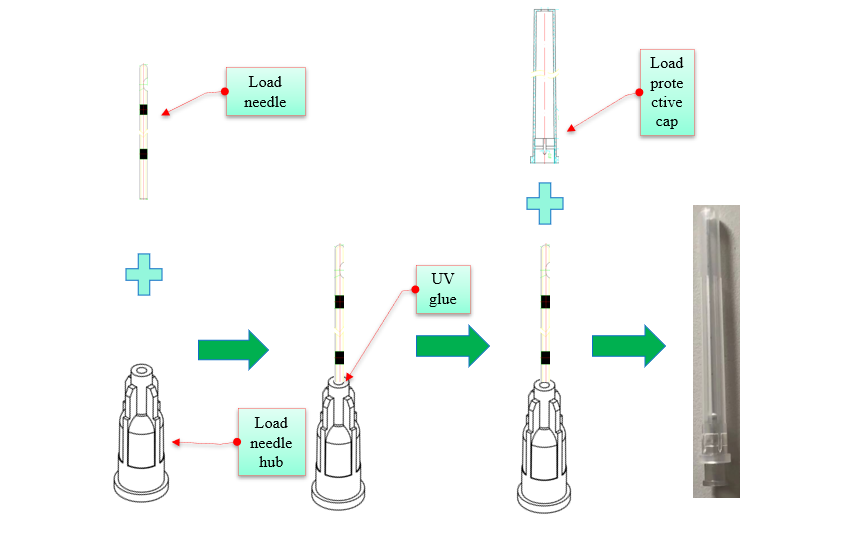

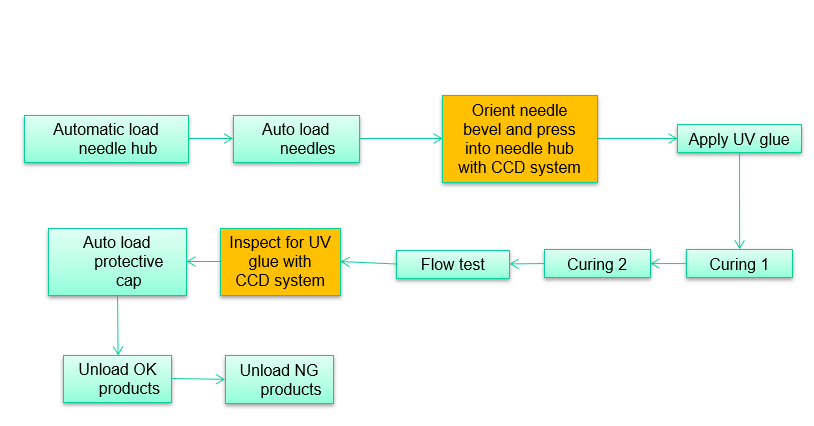

1、Process flow chart:

1) Automatic feeding needle hub

2) Automatic feeding needle with CCD system to control needle direction

3) Press the needle into needle hub

4) Apply UV glue and with CCD system inspection

5) Curing

6) Flow testing

7) Automatic feeding protective cap

8) Unload finished products

2、Machine Functions:

1 ) Automatic loading components

2 ) Production data can be traced

3 ) Apply UV glue , Curing , Vision inspection

4 ) Monitoring forming shape quality by CCD

5 )High efficient and capacity 900~1500PCS/H

3.Details Machine features:

1) Use vision system to check needle tip quality and needle length

2) Blunt needle tip silicification and silicone oil cleaning station, silicone oil shall not splash to other areas;

3) The equipment can feed needle hub, adjust, set and control needle orientation, apply UV adhesive,

4) Add protective cover around to protect the UV light from direct exposure to prevent operator eyes.

5) Data statistics for failed products is divided into two parts, failed products on the left and right zones of the station statistics

4、lead time

4 months

5、Packaging

Wooden case

6、warranty time

1 year

7、After-sales service

Support 7*24H,training support,Installation, wear parts..

Automatic Assembly Machine for Blunt Needle

1、Process flow chart:

1) Automatic feeding needle hub

2) Automatic feeding needle with CCD system to control needle direction

3) Press the needle into needle hub

4) Apply UV glue and with CCD system inspection

5) Curing

6) Flow testing

7) Automatic feeding protective cap

8) Unload finished products

2、Machine Functions:

1 ) Automatic loading components

2 ) Production data can be traced

3 ) Apply UV glue , Curing , Vision inspection

4 ) Monitoring forming shape quality by CCD

5 )High efficient and capacity 900~1500PCS/H

3.Details Machine features:

1) Use vision system to check needle tip quality and needle length

2) Blunt needle tip silicification and silicone oil cleaning station, silicone oil shall not splash to other areas;

3) The equipment can feed needle hub, adjust, set and control needle orientation, apply UV adhesive,

4) Add protective cover around to protect the UV light from direct exposure to prevent operator eyes.

5) Data statistics for failed products is divided into two parts, failed products on the left and right zones of the station statistics

4、lead time

4 months

5、Packaging

Wooden case

6、warranty time

1 year

7、After-sales service

Support 7*24H,training support,Installation, wear parts..